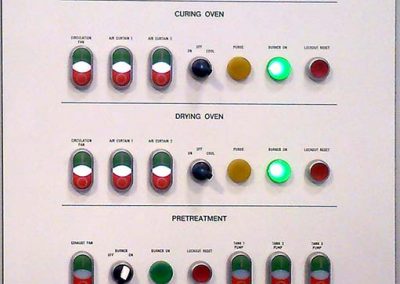

Curing Ovens

We pride ourselves on building good quality, safe and efficient hot air recirculating ovens – these are curing ovens. We build a selection of curing ovens from batch system box ovens, multi pass online ovens, online tunnel ovens to drying ovens. We offer a full range of sizes to meet customer requirements.

OVEN CONSTRUCTION:

All our curing ovens are designed for long-lasting durability and equipped with high-quality fan units, burners, and control systems to ensure minimal operational issues. The goal is to provide our customers with reliable and efficient performance. Each curing oven is constructed using a modular panel design. This design approach not only simplifies transportation but also allows for easier assembly on-site. It also offers flexibility for future modifications, whether you need to change the size of the oven or relocate it entirely. For smaller batch box curing ovens, we can manufacture them as a single unit, depending on size, which further reduces on-site assembly time.

The panels of our curing ovens are built using either galvanized or stainless steel sheets, depending on customer preference or the specific needs of the application. These sheets are packed with high-density RW5 rockwool insulation. This insulation is critical in minimizing heat transfer between the inner and outer panels, making the curing oven highly energy efficient. Additionally, we use minimal connectors between the inner and outer sheets to further reduce conductive heat loss. The thickness of the panels can be customized according to the client’s specifications, with available options ranging from 100mm to 150mm of RW5 rockwool.

The roofs of our curing ovens are also constructed using modular sections, which are insulated with high-density RW5 rockwool. These roof sections are designed with explosion relief features to ensure safety in high-temperature environments. The burner box heat chambers are constructed with a fully welded 3mm mild steel inner case. These chambers are then insulated with RW5 rockwool and clad with galvanized steel to maintain heat efficiency and durability. Inside each curing oven, we use a high-temperature centrifugal plug fan that effectively circulates hot air throughout the oven via a duct system.

We rely on top-quality Lanemark burners, which are available in either a hi-low setting or a fully modulating gas and air configuration, depending on the specific needs of the user. However, alternative burners can be installed upon request. With a focus on quality, efficiency, and safety, our curing ovens are designed to meet the varied needs of our customers.